USED MACHINERY

We regularly offer (revised) used machines.

Interested? Be sure to contact our sales team!

RV53 (base)

- Equipped with: RO550 unwinder

- Maximum Foil Width: 550mm

- Features:

- Forming station

- Punching station

- Stacking unit

- Forming Area: Maximum 500 x 350mm

- Electrical Upgrades : Fully renewed electrical cabinet

- Control System : New Siemens control unit with touchscreen interface, replacing the outdated Schleicher system

- Safety Upgrades : All safety relays replaced

- Pneumatics: Necessary pneumatics replaced

SB74 c9/c10 (Skin- and blistermachine)

- Complete Overhaul : The machine has been fully stripped and rebuilt.

- Control System : New Siemens control unit with touchscreen interface.

- Electrical Upgrades:

- Fully renewed electrical cabinet

- All electrical components replaced

- Mechanical Refurbishment : Thorough mechanical inspection and upgrades completed.

- Safety Upgrades : New safety relays installed.

- Heating System : Upgraded to energy-efficient white HTS heaters.

- Aesthetics : Machine fully repainted in RAL7035.

- Current Configuration : Set up as a C9 machine, with the option to add a feeding table to upgrade to a C10 configuration upon customer request.

SB74d (base)

-

Design: Linear design for easy integration into production workflows.

-

Operation: Primarily electro-mechanical, ensuring energy-efficient and quiet operation with high cycle rates.

-

Setup: Quick changeover times for increased machine utilization and organizational flexibility.

-

Control System: Multiprocessor control with memory cassette for storing up to 10 product-specific programs (including settings like heating time, temperature, and cutting positions).

-

Heating System: Ring zone temperature control of ceramic heaters, allowing for uniform heating. Outer zones can be set to higher temperatures or turned off for smaller formats.

-

Capabilities: Suitable for both skinpack and basic positive forming operations, such as blister packs. The form table is water-cooled and adaptable to various formats.

-

Cooling Option: Option to install two vertical cooling fans above the forming area.

-

Carton Feed: Extended version with four positions activated by footswitch for single or continuous feed.

-

Longitudinal Cutting: Equipped with crush knives against a hardened roller, with pneumatic lift. Knives can be adjusted outside the machine for desired pack width.

-

Cross Cutting and Punching: Features combined cross-cutting and hole-punching for hanging holes. Hole punches are pneumatically clamped and adjustable.

-

Safety Features: Includes sensors to protect the longitudinal and cross-cutting blades from pack material lying in the cutting line.

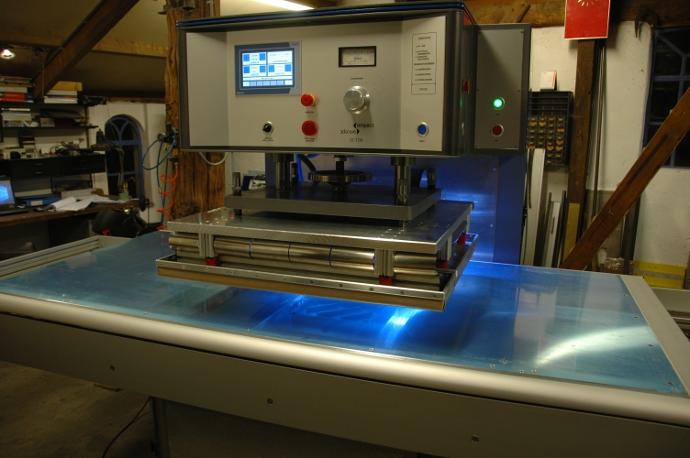

Compact Concept CC-T7/S

Specially built for producing small series of products in many sizes.

-

Welding power: 15 kW

-

Hours operated: +/- 1200

-

Welding range: 500 x 300 mm (adjustable)

-

Pneumatic

-

Electrode protection

-

Operation: fully automatic and protected

-

Automatic moving table: 900 x 2000 mm

-

Tool exchangeable with quick clamping lock

-

Maximum welding tool dimensions: 500 x 500 mm

-

Computer controlled timer for welding and cooling time

-

Automatic power setting

-

Power supply: 3 x 400V / 63A

-

Welding pressure digitally adjustable up to 1.5T

-

Standards CE/EMC: complete

-

Weight: 1500 kg

Compact Concept CS3/600

This machine is specially made for welding PU foil and has only been used for test series.

-

Welding power: HF power 3.2 kW

-

Welding range: 125 cm² maximum welding area

-

Pneumatic

-

Electrode protection

-

Servo foot control and two-hand safety control for the press

-

Lower table: 600 x 160 mm

-

Exchangeable tools

-

Maximum electrode length: 600 mm

-

Back to center electrode space: 100 mm

-

Timer for welding and cooling time

-

Welding power adjustable

-

Power supply: 3 x 400V+N / 16A

-

Maximum welding pressure 175 kg at min 6 bar incoming compressed air pressure

-

Standards CE and EMC

-

5 meter connecting cable and air hose

FIAB 8002

Pneumatic HF table welding machine in original working condition.

All documentation available.

-

Welding power: HF power max. 8 kW

-

Welding range: 300 cm² maximum welding area

-

Pneumatic

-

Electrode protection

-

Two-handed safety controls for the press

-

Sliding: 1000 x 550 mm

-

Exchangeable tools

-

Maximum welding tool dimensions: 1000 x 550 mm

-

Back to center electrode space: 300 mm

-

Timer for welding and cooling time

-

Welding power can be set manually

-

Power supply: 3 x 400V+N / 32A

-

Welding pressure is adjustable up to 1200 kg at min. 7bar incoming compressed air

5 meter connecting cable and air hose -

Weight: 650 kg

FIAB 8000PL

Rolling machine with 12-meter table

-

Welding power: HF power max. 8 kW

-

Welding range: 320 cm² maximum welding area

-

Controlled by compressed air

-

Electrode safety (anti-flash)

-

Two-handed safety controls for the press

-

Table: 750 x 12000 mm, with large gutter behind

-

Pneumatic toolholder for fixing tool

-

Maximum welding tool dimensions (Electrode): 1000mm

-

Back to center electrode space: 750 mm

-

Siemens PLC automation

-

Automatic Power setting

-

Power supply: 3 x 400V+N / 32A

-

Welding pressure is adjustable up to 1200 kg at min. 7bar incoming compressed air

-

15 meter connecting cable and air hose

-

Weight: 1250 kg

HISEN HW1523

HF welding press with 2 automatic sliding tables.

-

Welding power: 15 kW

-

Welding range: 525 cm²

-

Pneumatic

-

Electrode protection

-

Fully automatic start with safety screens

-

Lower table: 1050 x 900 mm

-

Extendable change plate

-

Maximum welding tool dimensions: 1050 x 900 mm

-

Timer for welding and cooling time

-

Automatic power setting

-

Power supply: 3 x 400V

-

Welding pressure is adjustable up to 1200 kg at min. 7bar incoming compressed air

-

Standards CE/EMC: 2010

-

5 meter connecting cable

-

Weight: 1500 kg

Interested in a machine or want more information?