At BNL, we've taken a trip down memory lane and revised a veteran machine, an ILLIG SB74c9. This project has turned this machine in an improved version that boasts modern technology, enhanced safety, and a revamped design. We're thrilled to share the story of this remarkable transformation.

From Green to White: A Fresh Start

The first step in this journey was to strip the old machine down to its core. Once we'd removed the layers of time and use, we gave the chassis a fresh coat of white paint. This revitalized its appearance.

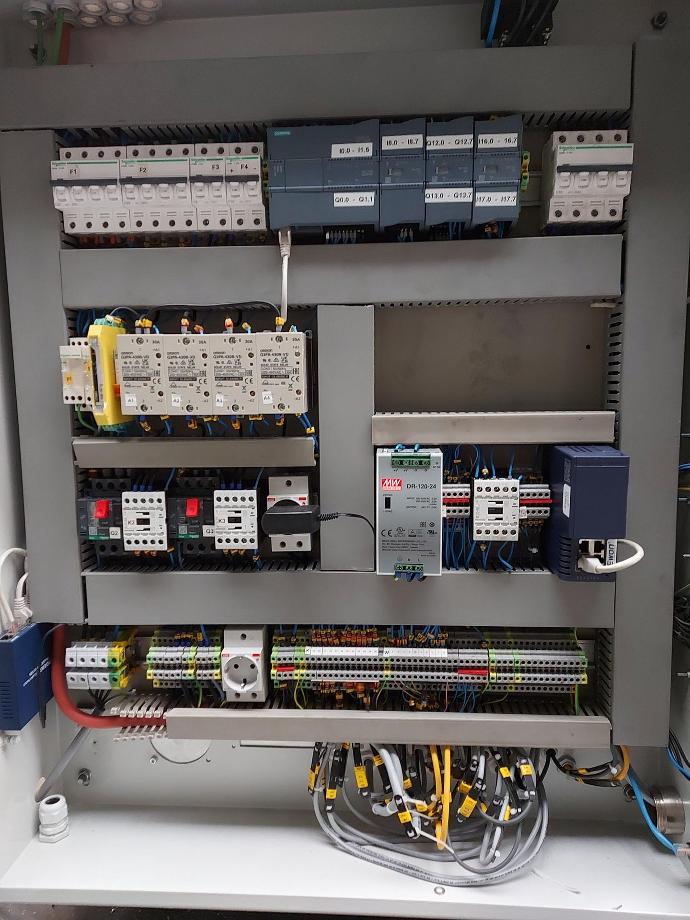

The Heart of the Transformation: All-New Components

The machine underwent a extensive rebuild with the integration of brand-new components. We invested in a state-of-the-art Programmable Logic Controller (PLC), enabling the machine to adapt to our customers' specific needs more effectively. A completely new program was developed, tailored to optimize the production process.

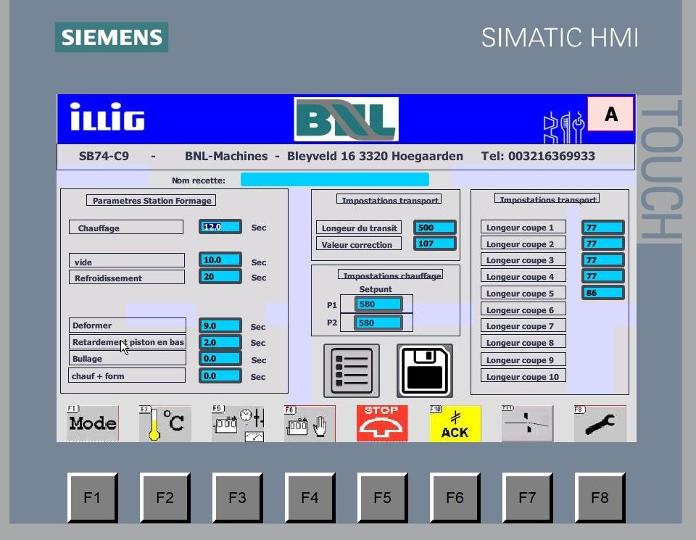

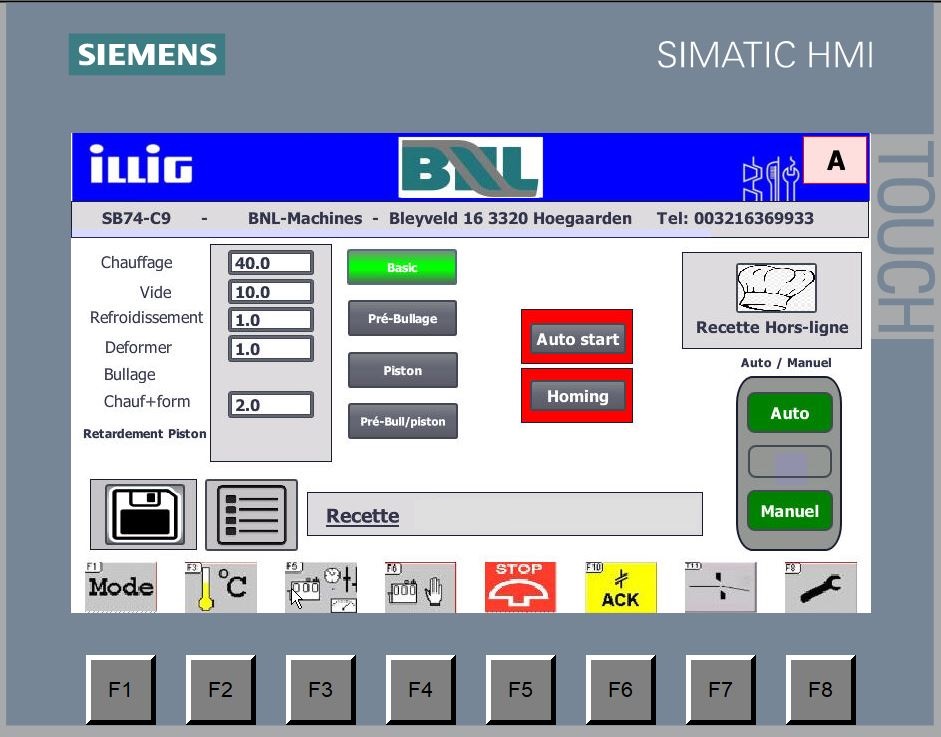

Control at Your Fingertips: The New Control Panel

The machine's user interface was updated with a modern, intuitive Siemens touch screen control panel. Now, operating this SB74c9 is more user-friendly and efficient than ever before.

Safety First: New Safety Features

Safety is paramount in our workplace, and the updated SB74c9 reflects that commitment. We introduced new safety features, ensuring the well-being of the operators.

Precision in Every Punch: The Power of New Motordrives

One of the standout improvements is the installation of a new motordriver for the punching mechanism. This offers precise positioning, resulting in faster cutting. Now, detailed contours are achieved through a punching knife, promising an high level of precision.

Unlocking the Advantages

Fully Automatic Production: Say goodbye to manual operations. The machine now works seamlessly, allowing for uninterrupted production.

Large Film Roll Capability: Thanks to the combination we made with a capable unroller (RO550), this SB74c9 can handle large film rolls with ease.

Fast and Precise Cutting: The new punching control ensures rapid, precise cutting, reducing production time and waste.

Detailed Contours: The punching knife enables the machine to create complex, detailed contours with finesse.

User-Friendly Operation: The touch screen control panel simplifies machine operation, making it accessible to all operators.

Enhanced Safety and Error Messages: The updated safety features provide real-time feedback on the machine's status and any potential errors, promoting safer and more efficient operations.

In conclusion, this SB74c9's transformation is a demonstration to our commitment to innovation and excellence. We've taken an aging machine and updated it completely, equipping it with the latest technology and safety features.

We look forward to sharing more success stories and innovations with you. Stay tuned for more exciting updates from our workplace!